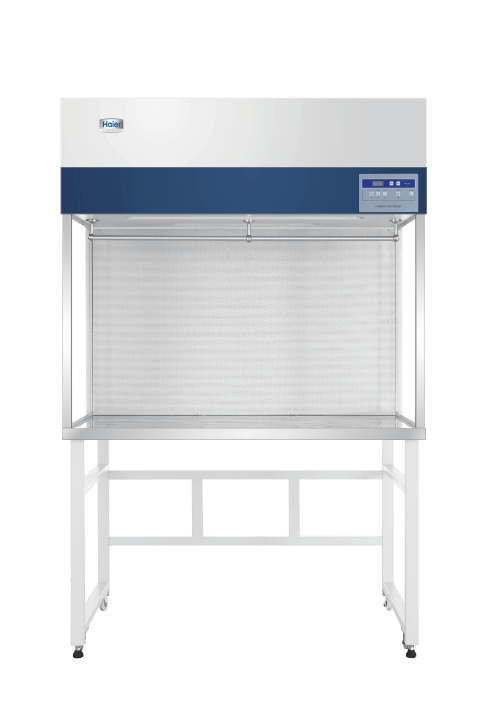

Within our range, we have various laminar flow cabinets to ensure a sterile and safe working environment. Do not hesitate to contact us to select the right solution together.

Our laminar cabinets feature many technologies and are certified. They are suitable for a wide range of applications in various sectors, including pharmaceutical, clinical, life science research or microelectronics manufacturing.

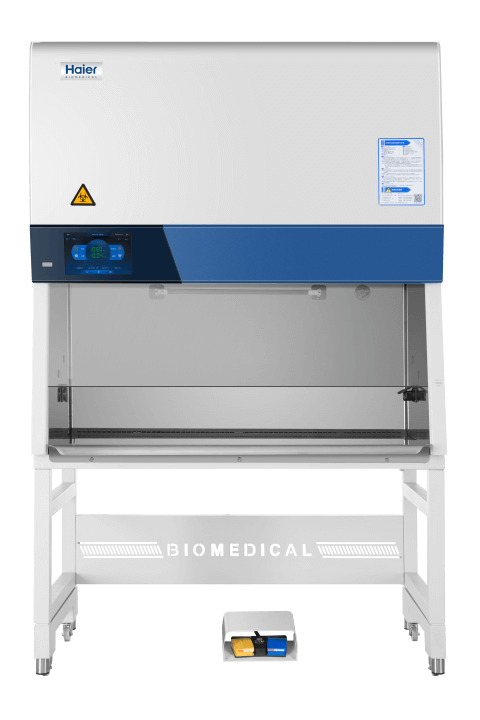

A biosafety cabinet is used in laboratories to protect both the user, the product and the environment from biological hazards.

So how do you choose the right biosafety cabinet? It can be confusing for end users, especially because of the different standards used.

There is also the newer European standard, which defines three classes but does not prescribe specific types. Within Europe, the European standard must be followed, but it does not provide detailed guidelines. However, about 95% of biosafety cabinets in Europe fall under class II A2.

This type protects the user and the environment from biohazards by drawing air into the cabinet and blowing it into the laboratory through a HEPA H14 filter at the top of the cabinet. This means that unfiltered air can pass by the product or test. In practice, this type is rarely used because cross-contamination with air is usually a problem.

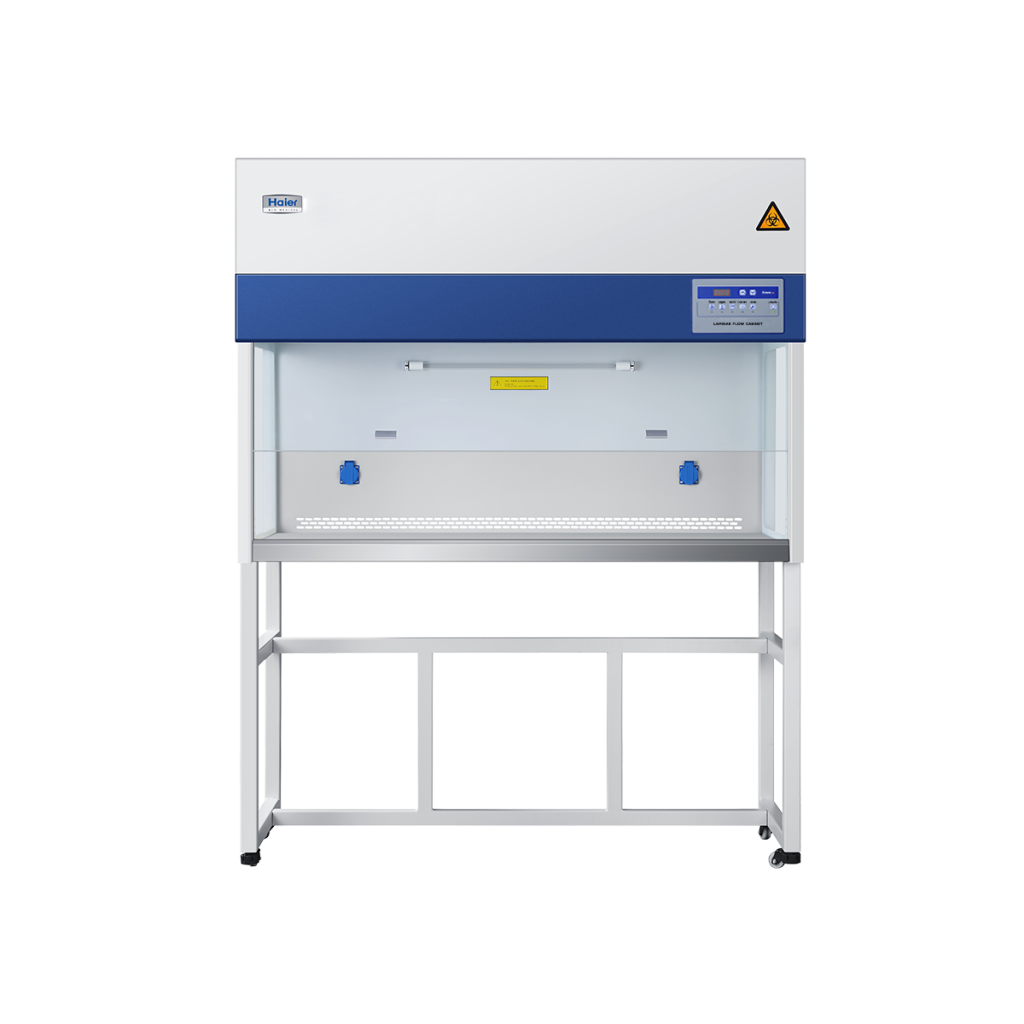

Horizontal laminar flow cabinets, crossflow cabinets, "clean benches" are often found in laboratories. In this case, sterile air is blown over the sample to be treated directly towards the manipulator. However, in no case can they be considered biosafety cabinets as no protection for the manipulator nor the environment is provided.

This type provides protection for both the user and the environment against biohazards and also prevents cross-contamination with the laminar air in front of the samples. The European standard leaves the choice of Class II type to the end user, as long as specific test criteria are met. In practice, Class II A2 is often the most common biosafety cabinet.

When working with chemicals, Class II A2 is usually connected to the building's ventilation system via a thimble duct. This requires only a specific flow rate and no exact control. Type B1, B2 and C1 are designed to use biohazards and chemicals in the same cabinet. However, these need very precise control, which requires an independent fan and ventilation system, making the installation more expensive. In practice, it usually makes sense to consider B1, B2 or C1 when working with large quantities of toxic or explosive chemicals. Indeed, Class II A2 recirculates 70% of the air in the cabinet, which can lead to vapour build-up when using large quantities of volatile chemicals.

This type provides three-level protection similar to Class II, but there is complete physical airtight separation between the user and the product or test. Material must be entered through a sas and manipulation within the cabinet is done through gloves. This cabinet is usually only found in biosafety level 4 laboratories.

As for the use of chemicals within a biosafety cabinet, mild quantities can be used in a Class II A2 cabinet. However, it must be connected to the HVAC system via an extraction hood and piping. The flow rate of the HVAC system must be above a certain value. Another option is to use carbon filters, which some manufacturers offer. These filters, filled with activated carbon, can efficiently capture chemical vapours via adsorption. For large concentrations of volatile chemicals combined with biohazards, Class II B2 is the best choice.

A powder extractor sends the air back into the lab through a filter. As a result, it is not connected to the outside air of the HVAC system so there are no pressure differences. This will not affect the balance results when weighing. Powders are also heavier than air. In a conventional pull box, this air in the HVAC system will often have to take bends. Powders tend to accumulate in bends in the HVAC system. These 2 factors above make a powder cabinet the ideal solution for weighing powders.

Combined with a carbon filter on top of the powder cabinet's HEPA H14 filter, liquid chemicals can be weighed off if necessary.

Whether you are a hospital, university, research or production centre, we have the solutions to meet your specific needs.

Let our experts help you choose the right solutions for your organisation.